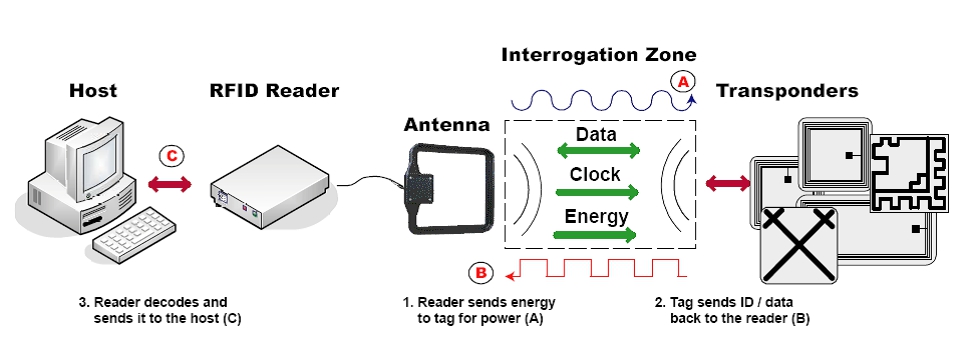

RFID is short for “radio-frequency identification” and points to a technology whereby a reader catches digital information encoded in RFID tags or smart labels via radio waves. RFID steers auto-ID technology to the next level by enabling tags to be read without a line of sight and, depending on the kind of RFID, having a reading range between a few centimetres to over 20+ metres. At a simplistic level, RFID systems include three major components: an RFID tag or smart label, an RFID reader, and an antenna. RFID tags include an integrated circuit and an antenna, which are used to transfer data to the RFID reader. The reader then transforms the radio waves into a more usable form of data. The data collected from the tags is then conveyed through a communications interface to a host computer system, where the collected information can be stored in a database and analysed at the following time. RFID Systems are operated in many industries to perform tasks such as: – Asset tracking – ID Badging – Personnel tracking – Counterfeit prevention – Controlling access to restricted areas – Inventory management – Supply chain management RFID provides many benefits over the barcode, especially the fact that an RFID tag can hold much more info about an item instead of a barcode scan. In addition, RFID tags are not responsive to the damage costs that may be incurred by barcode labels, such as ripping and smearing. What sets a possible RFID application apart from applications is the requirement to uniquely identify individual items instantly and more efficiently where traditional techniques usually fall short.

Limit Switches : –

Limit switches are used as pilot devices for magnetic starter control circuits, allows them to start, stop, slow down, or accelerate the functions of an electric motor. It automatically monitors and indicates whether the movement limits of a particular device have been exceeded.

Schneider Electric India offers OsiSense limit switches, primarily an advanced electromechanical device that contains an actuator linked to a series of contacts. It is a boon for industrial machinery that undergoes automatic operations. It serves the purpose of control switches that activate according to the movements involved in a machine’s performance.

Proximity and Presence Sensors : –

A proximity sensor is a non-contact sensor that detects the presence of an object (often referred to as the “target”) when the target enters the sensor’s field. Depending on the type of proximity sensor, sound, light, infrared radiation (IR), or electromagnetic fields may be utilized by the sensor to detect a target.

Encoders : –

An encoder (or “simple encoder”) in digital electronics is a one-hot to binary converter. That is, if there are 2n input lines, and at most only one of them will ever be high, the binary code of this ‘hot’ line is produced on the n-bit output lines. A binary encoder is the dual of a binary decoder.

Pressure Sensors : –

Pressure is defined as the applied force by a liquid or gas on a surface and it is usually measured in units of force per unit of surface area. Common units are Pascal (Pa), Bar (bar), N/mm2 or psi (pounds per square inch).

Safety Sensors and Switches : –

Safety sensor switches are used in machines and other industrial applications to prevent accidental contact with live electrical connections. Safety sensor switches work together with hinged, sliding, or lift-off guards and barriers. The power supply to the machine is disconnected as soon as the guard is opened.

Traceability and Access Control : –

Make the most of the openness with our RFID system. Enjoy the freedom of choosing the tags you need, while it automatically adapts to your network protocol. Easy to install, to connect and to set up, it’s ideally suited for object traceability, object tracking and access-control functions.